Workshop and Equipment (Updated 030125)

I've decided this page was getting a bit cumbersome! It took an age to scroll down it, so I've re-structured to make it a bit easier to read.

It must be true what they say: possessions do expand to fill the space available, as the last twenty years or so have seen something of an expansion in my 'toolkit'...! When I bought my house in early 2002 I had one old lathe and the usual DIY array of tools, mostly for car repairs.

Among the weaponry at my disposal now:-

Bridgeport 1ES Horizontal Milling Machine

Perrin Vertical Mill/ Drill/ Borer

Oerlikon Citocut 10i Plasma Cutter

Guyson Blasting Cabinet and Extractor

Bosch Cut-off Disc ('chop saw')

Bench-mounted sheet steel guillotine

Assorted Air Drills, Grinders, Wrenches, Cut-off disc, Nibbler, Sprayguns etc.

8" and 6" Double-ended Bench Grinders

Electric Drills, Angle- and Die-Grinders etc.

Bosch PMF180 Oscillating Cutter/ Sander

Dremel 3000, B&D 'Wizard' Multi-tools

Two-ton long-reach folding crane

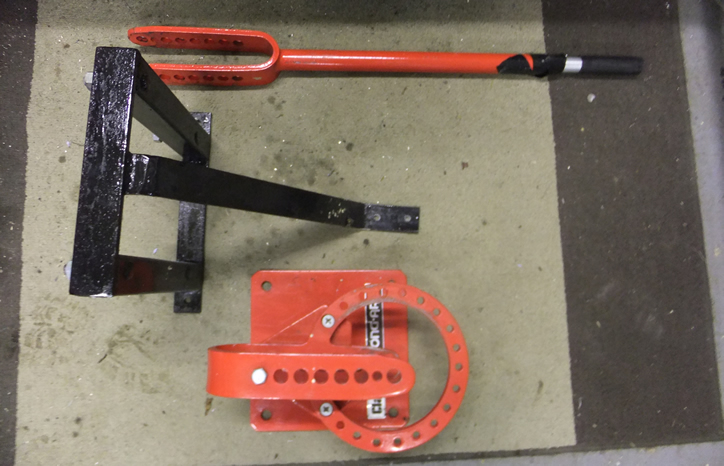

Motorcycle tyre changer (home built)

Tektronix 212 Portable Oscilloscope

Plus all the usual hand tools you'd expect and maybe a few more besides...!

Guyson Blasting Cabinet and Extractor

One of my first Ebay finds, this Guyson DBH2 was bought from a machinery trader in Daventry. The extractor (not shown) was a three-phase unit but I had a spare single-phase motor of the right size that fitted straight onto the fan.

The cabinet needed new gauntlets; these are an absolute fortune from Guyson as they're moulded to fit the triangular openings in the front of the cabinet (presumably done to make sure you buy their spares!). I made a mould and created two 'fillers' that allowed me to fit standard long black gauntlets, £12 a pair instead of £80! I also had to replace the viewing glass as it was blasted to hell, and the blasting gun ceramic nozzle eventually wore out necessitating replacement (with a tungsten one - £30!). Add to that the price of blasting medium and it's an expensive hobby (I reckon I must have spent about £500 on the sandblast by now; that would buy a lot of time at the powder-coaters - but it's damned convenient to have!). Quite by chance I came across a bag of glass bead media; unfortunately it gets pulled out by the extractor rather quicker than the 80 grit aluminium oxide, though it gives a much nicer finish on alloy parts. I found the limit of the cabinet's capacity as it was JUST possible to blast the sump from the Esprit's engine! I soon discovered that the glass viewing window needs regular replacement as it gets 'frosted' by flying grit. Taking a cue from modern cabinets I replaced the glass with polycarbonate and then went a stage further, wrapping it in clingfilm. So now I periodically just rip off the tattered clingfilm and re-wrap the polycarb and I can see what I'm doing for a few more months.

After several years the sandblaster had started to give erratic performance; the grit flow had dropped right off despite nothing being blocked or kinked. Eventually I realised that the blasting 'gun' has a tapered nozzle inside it which had stuck in position, making me think it was part of the main casting. The nozzle creates a venturi effect in the airflow which sucks the grit up from the cabinet hopper. As soon as I drifted the nozzle out I could see the problem; the inrushing grit had worn a hole through the wall of the nozzle so the air was leaking directly into the path of the grit from the 'lift' pipe, ruining the venturi effect. GIven that (a) I know how Guyson like to charge and (b) I had a lathe next to me, I opted to make a replacement nozzle from a buckshee bit of steel bar. Now here's a tip: if you happen to replace your nozzle, under no circumstances do what I did to test mine... i.e. stick your bare hand in front of the gun set at 100psi and press the tit...! Normal service, shall we say, has resumed.

Tucked away in the corner is my parts washer: bought new from an importer in Tyneside, I think it cost £27 way back when. It's a 10-gallon tank with recirculating pump, exactly the same as sold by Machine Mart and others. I use Jizer degreaser in it; the tank makers don't recommend you use anything other than water with a mild detergent but what bloody use is that? As you can see, Jizer does a good job of stripping paint as well as muck and oil. The collection of baskets, trays etc. helps prevent losing small items in the layer of 'clart' (as my grandma would have called it!) that collects at the bottom of the tank. Unfortunately, and bearing out the makers' advice, after about ten years of being immersed in Jizer the pump housing disintegrated. It's only a cheap pond pump, but rather annoyingly I threw out a spare pump that I'd had for years, about a fortnight before this one died.

This old American-made unit was written-off by being connected to the wrong mains voltage (not by me!) which fried all the control electronics, but it transpired that the driver PCB that generates the high-frequency waveform to make the quartz oscillation pads work was repairable. I found an old mechanical timer from a washing machine (hence the large brown knob that looks suspiciously like it came from a Hotpoint!) and cobbled it together. A wire basket from Tesco's kitchen department provides a means of dunking grubby parts in and I use the usual detergent that is sold for use with these cleaning tanks; the only downside is that the heater doesn't work but for the odd occasion I use it, it's not important.

The generous mate who gave me the Oxford 120s MIG welder also gave me his old air compressor! Originally a SIP 'Workshop' range unit, its 100 Litre red receiver had been repainted a fetching shade of metallic green. But did I care? Not likely! Paul C had decided that his car-spraying days were over as he'd met a guy who could do the work for him at a price too good to miss, so the compressor was duly heaved into my van and took up residence here. I blew the cobwebs off, cleaned out the filter and, er, well that's it, really! It sits there and compresses air. Next, of course, I needed some air tools.... and once again, Ebay is your friend! :-D

Well, apart from the larger pistol-grip drill, which my dad gave me. He'd been given it by one of his clients years back, but his portable compressor couldn't run it. Made by DeSoutter, it's in fine working order, though it must have lain unused for 25 years! The only problem I had was finding a chuck key to fit it; it's a bizarre size.

The sprayguns were gifts too, from a mate who did custom paint jobs on motorcycles. Essentially they were old guns he'd thrown in the cupboard after they got choked with primer once too often, but with a good clean they're more or less serviceable.

Ebay turned up most of the other air tools: two DeSoutter 1/4" drive wrenches, angle grinder, straight drill, small pistol-grip drill, impact screwdriver (all DeSoutter), grease gun (even NuTool can't go far wrong with a grease gun).

The tyre inflator was a B&Q clearance special when they were switching from SIP air tools to Rockworth or whatever Chinese junk it is they do now. I also have a couple of those SIP cut-off tools with the small (80mm) disc and a micro die-grinder. On the subject of junk, Aldi and Lidl stores have periodic 'special offers' of pneumatic equipment. Normally I'd have give this stuff a wide berth, but there are mitigating circumstances, not least the three-year warranty that they offer... and given that several of the items they were selling seem to be identical to those sold by Machine Mart at twice (or more) the price, I'm prepared to give them a chance. So over time I've added to my air-tool cabinet spare regulator/filter/oilers; an impact wrench; a sheet-metal nibbler, needle de-scaler and a spot-blasting gun!

One day, I went to a local powder-coating place with some components from work. We'd used them for years but this time the owner was really shirty about 'those bits of crap' so I went elsewhere. I got one of the lads to demo the actual process to me, and that led to me mooching round the 'net looking for equipment. Professional kit of course costs a fortune, but I came across this system from 'Electrostatic Magic'. In essence it's a modified blow-gun fitted with a 'paint' hopper and an electrode system that applies a charge to the plastic powder as it's blown through by compressed air. The charge (several kV!) is generated by the power supply unit when a footswitch is pressed.

Obviously another Chinese product with a manual written in gobbledegook, it retails for about £100 (or it did then, I haven't checked lately!). Now I know that would buy quite a lot of time at the powder-coaters, but that bloke pissed me off so I'd rather he doesn't get any more of my, or the company's money (in fact something like 26 years later I still haven't been back and still refuse to recommend them to anyone). I'd had the powder-coating system for several months before I finally got round to using it; the results of my first attempt can be seen here!

I acquired this 2-tonne long-reach crane back in 2005. Identical to this one, it's the one I used to lift the Esprit engine in and out; when I returned it to the owner, he said he thought he had no further use for it and I could have it for half what he'd paid only a few months earlier! Well, it would have been rude not to, so I did.

Bought from a fellow forum member (sadly no longer with us) over at migwelding.co.uk, I thought this might be a useful bit of kit... although 7 years on and I don't think I've bent anything with it yet! It's one of these.

Mine came with a fabricated bracket to allow mounting it on a convenient wall pillar rather than a bench:

I bought this Clarke (Machine Mart) toolchest from a work colleague: he'd bought it in a flurry of enthusiasm for restoring a VW Corrado (!?) but never even took it out of the box! At 30% less than he paid for it I decided I could find room for it ;o)

One of those bits of kit for which there's probably no substitute. If you're going to twiddle with your fuel injection (and I do :D) then you need an idea of what the car is chucking out at the back. Ye olde Rover V8 has no fancy closed-loop lambda-sensing save-the-children-and-think-of-the-kittens control on it so it's easy to get the thing running, but way out of adjustment. I bought this meter new, way back last century and it's had little use over the years - but it's there if I need it (or rather, it will be if the last person to borrow it ever brings it back. Come on, it's been 15 years - at least. You know who you are.)

Morgan Carbtune (Mercury Manometers)

Yes, another piece of equipment without which the addicted tinkerer would struggle :D This set was actually a xmas gift many moons (and ex-wives) ago and, like the CO meter, has spent many years tucked in a cupboard... but when your carbs are out of balance (or an engine fault makes it appear that way) there's no substitute. Morgan haven't made this variant for years - decades, even - owing to some namby-pamby nonsense about mercury being a hazardous substance that can't be sent through the post... I mean come on, when did you last hear of Postman Pat dying from quicksilver poisoning? ;o)

Tektronix 212 Portable Oscilloscope

Quite possibly my favourite bit of test gear of all time. We had some of these scopes at work a couple of decades ago and when I started making modifications to the TVR's injection system and wanted to learn more about what was going on I decided I needed to be able to look at the injector pulses etc. whilst on the move so I saved up my pocket money, watched Ebay and eventually picked up this one (admittedly not the cheapest deal I ever got but sometimes you just have to push the boat out). The scope has only one real drawback and that is that being American it is a 110V-only unit so can't run or charge from UK mains without a transformer. A small price to pay! The 40 year old Ni-Cd batteries eventually died a death and I have yet to replace them, they're some oddball size that I can't find at a price worth paying. For now there's a length of wire hanging out of it that lets me connect a 12V supply, so it's not the end of the world...